SIMULATION AND PROTOTYPING

Exclusive design services that ensure the feasibility of the final product

Do you need to manufacture a part that requires a new stamping die, designed from scratch?

Elitech’s services will ensure the project’s feasibility, eliminating the risk of equipment downtime and reducing scrap.

Thanks to our simulation and prototyping services, we will design an incredibly detailed model of your new die.

Our analyses will allow you to evaluate the feasibility of the project in the design stage. This way, you will anticipate any problems that would otherwise require costly and time-consuming changes during the tryout stage.

Your new stamping die will minimise the manufacturing time and reduce the costs of your new part’s production.

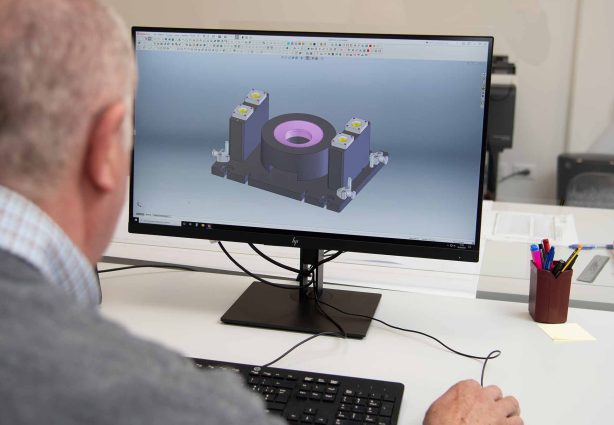

Simulation is a virtual evaluation of the die.

After our experts have examined all the technical aspects of the part you want to produce, we will design your die using specific modeling software.

This will allow us to identify the critical points in the part right away. Most importantly, we will provide you with all the instructions you need to make adjustments or explore viable alternatives before moving on to prototyping.

At the end of the simulation, you will receive a 3D drawing of the new die that will ensure you a flawless stamped part and a smooth production process.

Prototyping

We will build a prototype of your new die to assess and validate the design before starting its production.

It’s a fast and easy process that will allow you to minimise die testing costs and achieve full productivity in the shortest possible time.